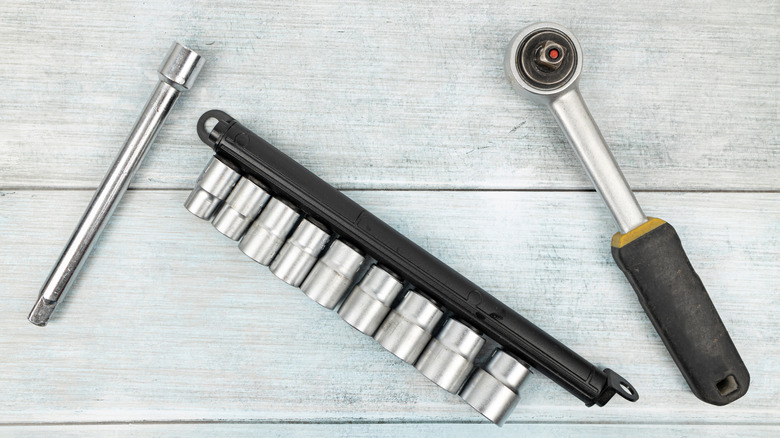

A ratcheting wrench is a tool that utilizes a ratchet mechanism to allow movement in one direction while blocking it in the other. This mechanism, which includes a pawl and a gear, enables the ratchet to hold a fastener while turning it back for another turn. Consequently, it simplifies tasks and reduces effort since it eliminates the need to detach and reattach the tool with each action. Patented by J.J. Richardson, the ratchet wrench features interchangeable square design sockets in various sizes.

Advertisement

Before the ratcheting wrench, the wrench has traditionally been used for tightening nuts and bolts since the 15th century. Early versions were utilized by the Greeks and later by the Egyptians and Romans. Centuries later, during the Industrial Revolution in the 18th century, the need for new tools arose, leading to the first patented wrench by Solymon Merrick in 1835. Then, in 1863, J.J. Richardson introduced the ratcheting wrench, equipped with removable and interchangeable sockets.

Robert Owen has also been recognized as an inventor of the ratchet wrench, although his patent was filed 50 years after Richardson’s and featured a different design mechanism with two rotating heads for each direction, unlike the single-head version from Richardson. Due to the benefits of the ratcheting mechanism and interchangeable sockets, numerous companies have crafted and enhanced equivalent tools. Today, the latest versions are electric-powered, allowing consumers to select from many brands of cordless ratchet wrenches available in the market.

Advertisement

One tool with many uses

The ratcheting wrench is primarily used for tightening and loosening nuts and bolts, making it an essential part of any home or work toolkit. It proves especially useful in tasks that require repeated rotations or in tight spaces where a standard wrench cannot fit. The advantages of using a ratcheting wrench include convenience through reduced muscle strain and fatigue due to its one-way functionality. Additionally, its adaptability allows for use with various sizes and shapes of sockets, making it suitable for multiple applications.

Advertisement

Although it might appear straightforward, using ratcheting wrenches demands care and proper techniques. A common mistake is pairing an incorrect socket size, which can strip or round the bolt head or nut, or lead to slippage that may cause injury. Also, employing the ratcheting wrench for tasks meant for a different tool, like a torque wrench, can break bolts or strip threads. Accuracy in using the tool is crucial, ensuring the ratchet points in the correct direction for smooth rotation and confirming that the ratchet is fully engaged with the socket while applying torque.

Because it enhances work efficiency and speed, the ratcheting wrench is invaluable in various industries, such as construction, machinery maintenance, and auto repair. A ratcheting wrench, like any tool, requires regular maintenance, including cleaning and rust protection, to maintain its effectiveness and prolong its lifespan. Most importantly, as using the ratcheting wrench involves applying force, practicing tool safety is essential to ensure the user’s safety and mitigate the risk of injury in the workplace.

Advertisement